FEA Simulations

VALIDATE YOUR DESIGNS BEFORE THE FIRST PROTOTYPE

Our Finite Element Analysis (FEA) services deliver structural insights that accelerate development, reduce costs, and bring reliable products to market faster.

We simulate real-world conditions to predict component performance under stress, vibration, thermal loads, and fatigue. This enables early design optimization, avoids costly redesigns, and demonstrates compliance with industry standards—before fabrication begins.

Types of numerical simulations

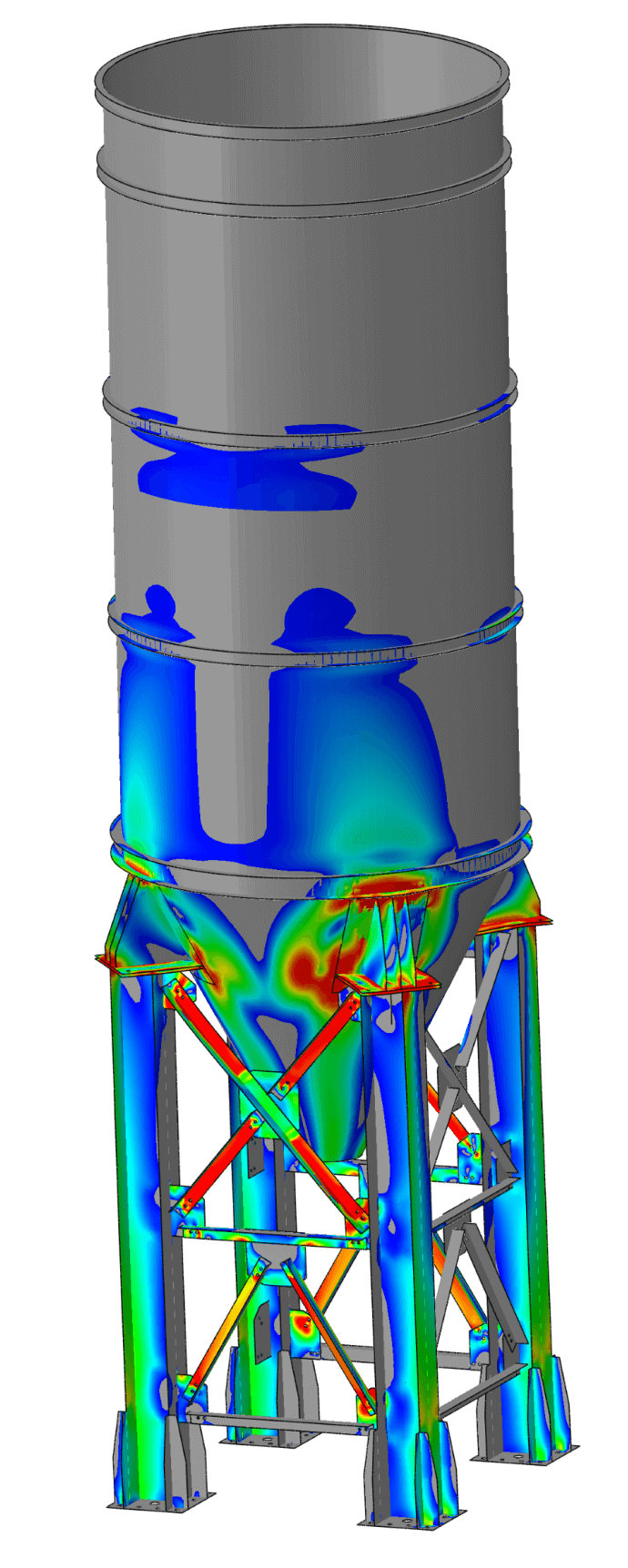

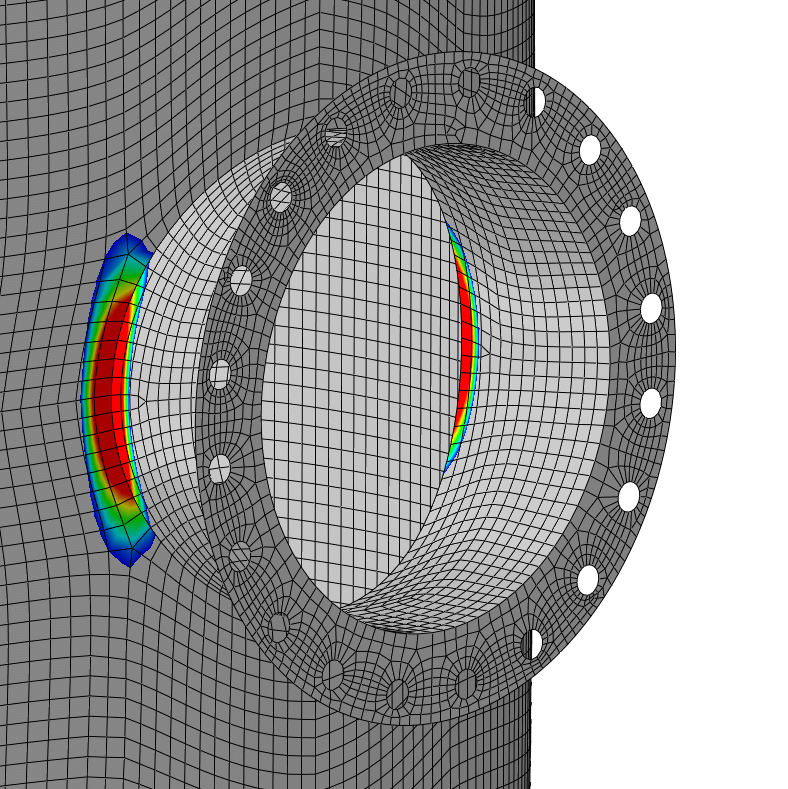

Structural analysis

Our analyses

- Nonlinear analysis (Complex nonlinear problems including nonlinear contact, material properties and large deformations, buckling, creep, etc...)

- Structural analysis (Code compliant analysis of civil and industrial structures.)

- Pressure vessel analysis (ASME Section VIII Division 2)

- Pipeline stress analysis (Welding stresses with safety assessments, ASME B31.3)

- Thermo-mechanical simulations (Thermo-mechanical loads, expansion of materials, residual stresses)

Dynamic analysis

Our analyses

- Multi-Body Dynamics (Complex mechanisms like landing gears and suspensions)

- Normal modes (Natural frequencies and mode shapes, Complex eigenvalues, preloaded eigenvalues)

- Frequency response analysis (Direct integration and mode based steady-state response analysis)

- Acoustic and NVH analysis (Boundary element based acoustic analysis, fully acoustic analysis)

- Random response analysis and Response spectrum analysis

- Radiated power analysis

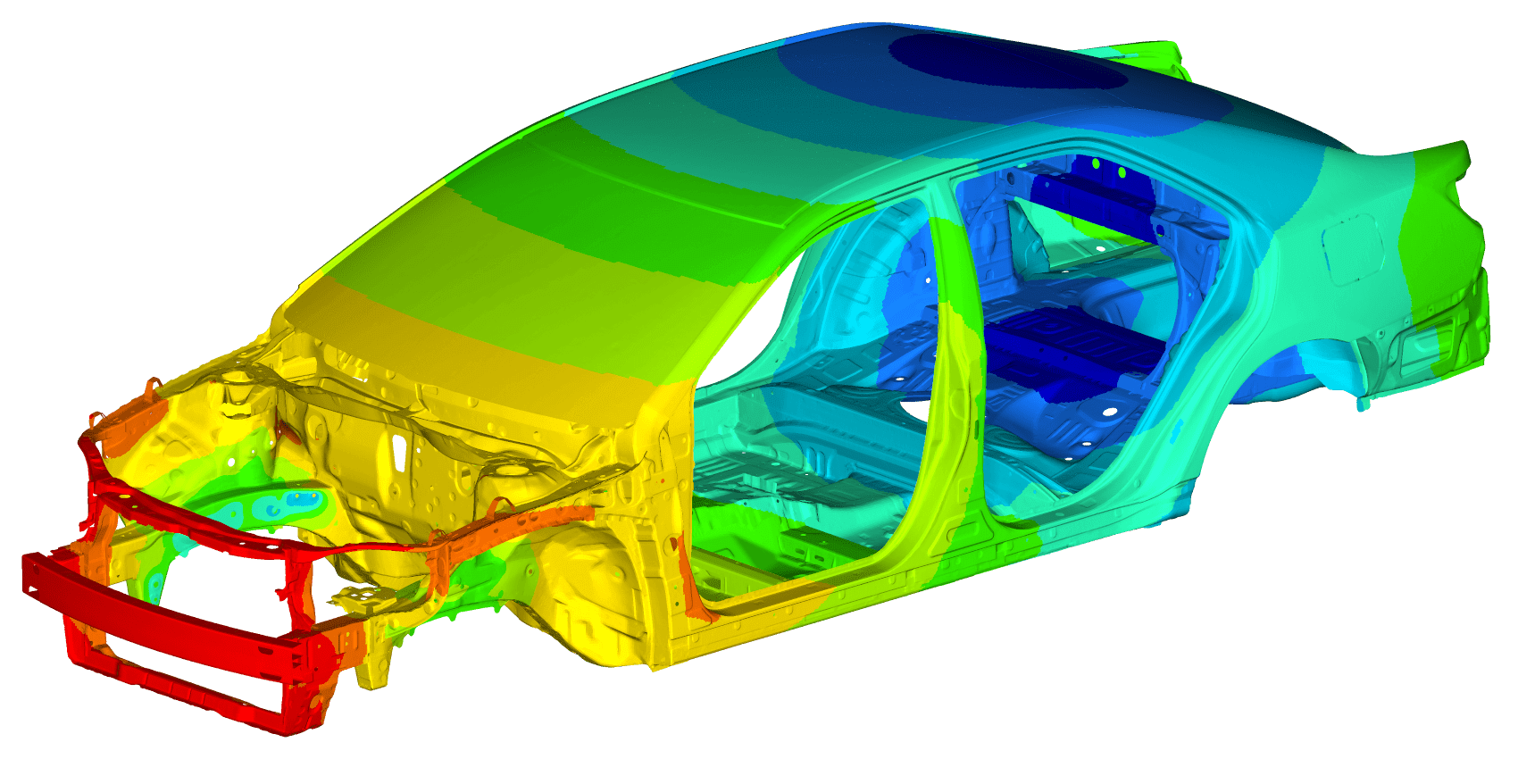

Crash analysis

Our analyses

- Crash analysis (Complex structures like a vehicle, mobile phone, ect..)

- Strain-rate dependent materials

- Post-buckling effects

- Explicit dynamic (Complex dynamic structures like crankshafts)

- Blast simulations (soils, fluids and structures)

- Drop test simulations

Fatigue

Our analyses

- Static analysis based fatigue (S-N curve, mean stress correction, residual stresses )

- Vibrational fatigue (Based on random response analysis)

- Thermomechanical fatigue (Power electronic thermo-mechanical analysis)

Composite material

Our analyses

- Predictions of components made from high-performance materials

- Inter and intra laminar damage modelling (Ply failure and delamination)

- Multi-scale analysis (Larger structures with embedded domains)

- Impact simulations on laminates (Stacked-shell approach)

- Micromechanics (Homogenization and localization)

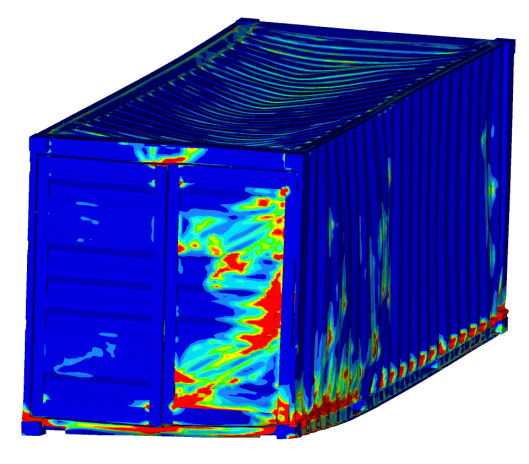

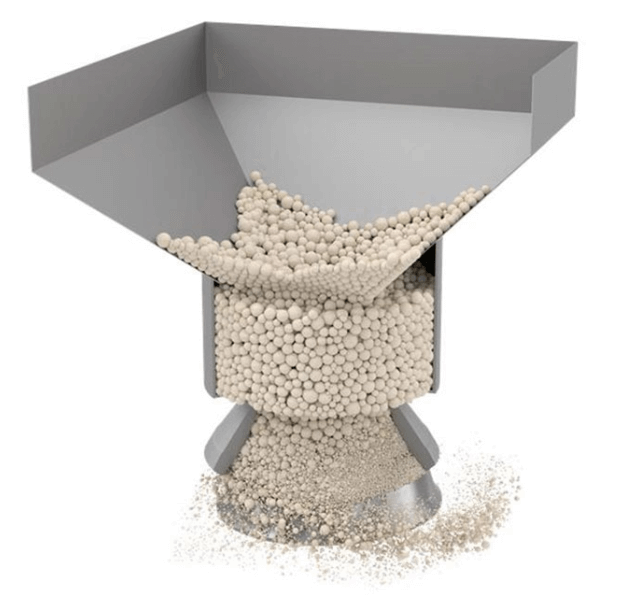

Bulk material analysis

Our analyses

- Discrete element method for bulk analysis

- Complex bulk material models

- Conveyor and hopper analysis

- Bulk material loading extraction

- Ware analysis

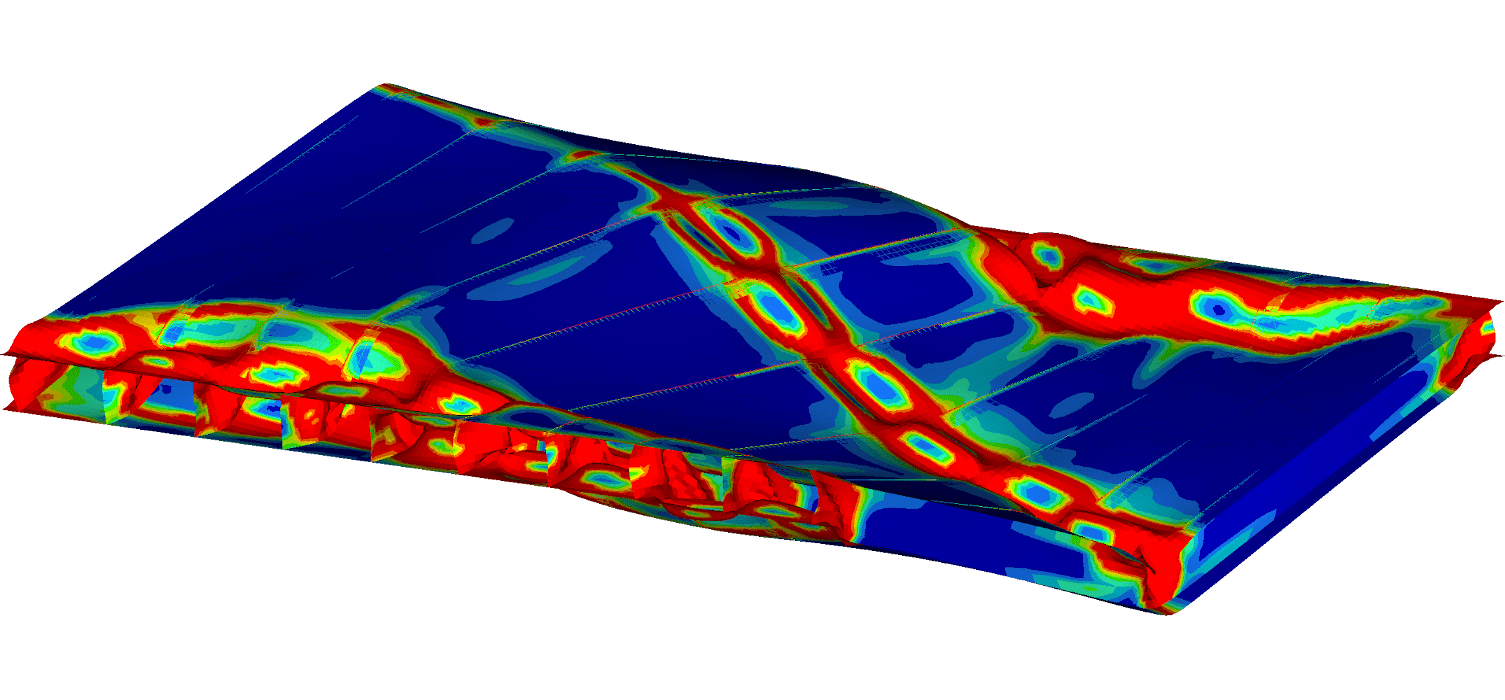

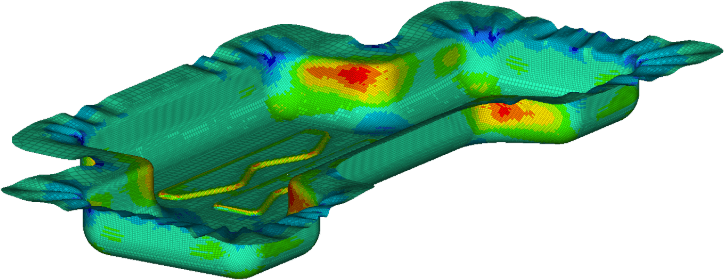

Manufacturing analysis

Our analyses

- Injection molding (Simulation of flow, pack and warping stages. Optimization of cooling and molding parameters for higher productivity)

- Forming (Analysis of deep drawing for single and multi-stage tools. Optimization of the die for the springbuck effect.)

- Casting ( Gravitations, low and high-pressure casting processes)

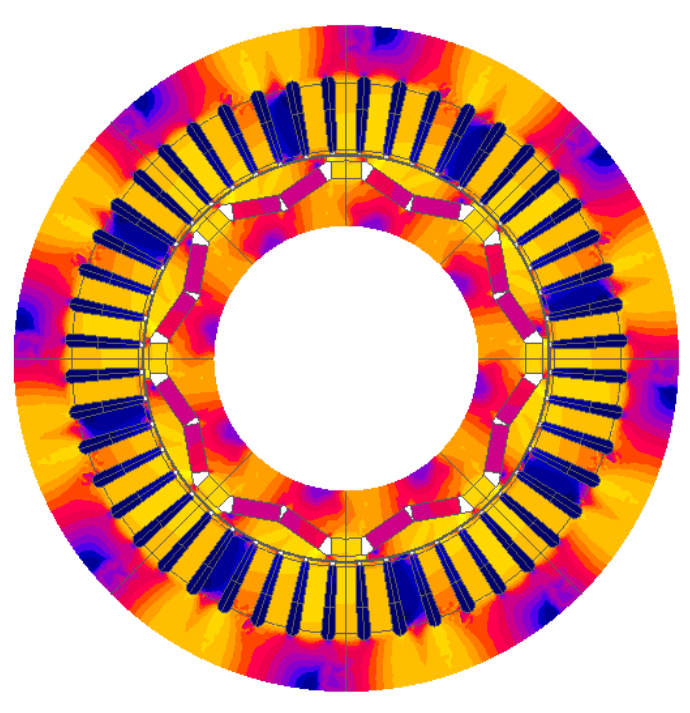

Electromagnetic analysis

Our analyses

- PMSM analysis (Concept design, Torque speed characteristics, Cogging torque, back EMF harmonic study, Id-Iq maps, Eddy current losses, NVH)

- Induction motor analysis (Analysis of entire IM period, study of harmonics, starting analysis)

- SMR motor analysis (switch on-off angle optimization, losses calculation, current chopping techniques)

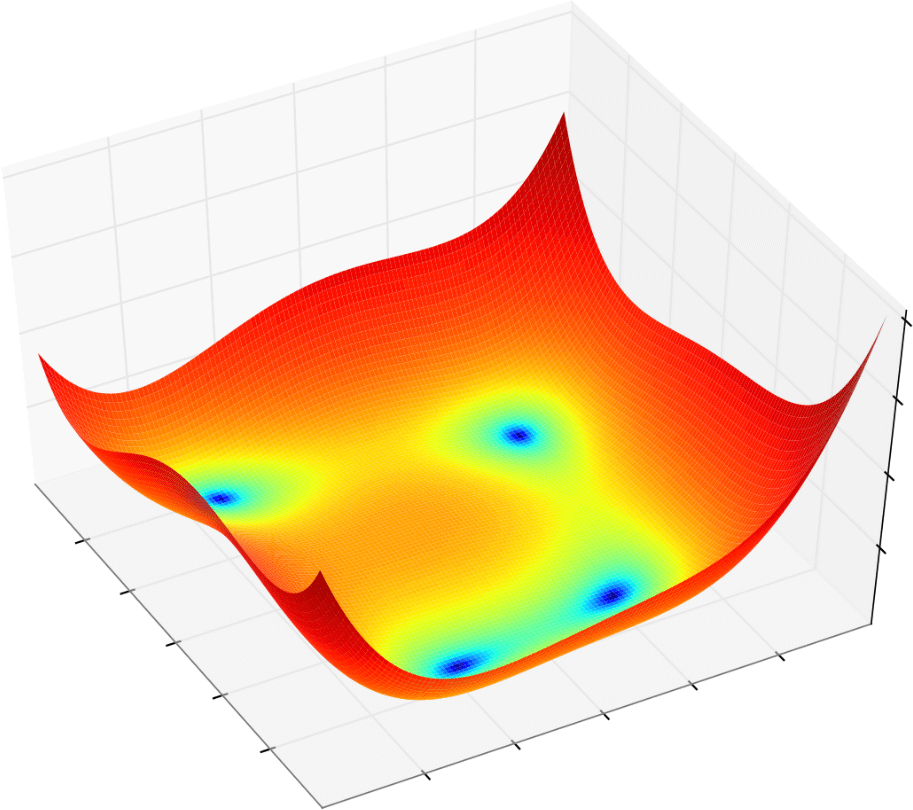

Numerical optimization

Our analyses

- Parametric optimization - (Shape optimization, thickness optimization, composite optimization, material characterization)

- Topology optimization - (Complex design spaces, multi-objective and multi-constraint optimization, manufacturing constraints)

- Topography and shape optimization - (Bead optimization, metal sheet thickness optimization, shape optimization)

Why choose us?

Industry experience

Trusted by companies in aerospace, automotive, heavy industry, and energy.

Optimization focus

We don't just validate – we enhance performance and reduce weight.

Action-driven results

Receive clear recommendations and data-backed guidance for design improvement.

Thank you for reaching out to Simbased. Your form has been successfully submitted. We'll get back to you shortly.